Powerful New GPR Tool Helps Contractors Ensure Road Pavement Quality

Have you ever been a fly on the wall of any state department of transportation? If so, I’m sure you heard discussions on how to improve road pavement quality and extend service life. Every state devotes a good portion of its budget to roadway and pavement improvements – and officials are always looking for ways to make the most of their limited budgets.

One avenue being pursued is new technology that can accurately measure whether there is density uniformity throughout a pavement layer. Why is this important, you may ask? The answer is that numerous studies show that getting the right pavement density is a crucial factor in increasing pavement life.

Pioneering Research in Maine

One real pioneer in the field is Dale Peabody, Director of the Transportation Research Division at Maine DOT. He and his team use a variety of tools to test compacted asphalt mixtures, and moisture damage susceptibility. They have also conducted research on better mixes.

This team is equally focused on the material lay down side, for example by specifying that equipment contractors use materials transfer vehicles (MTVs) to ensure a more uniform and longer lasting road surface. They also include ride smoothness and road joint specifications and use quality control/quality assurance (QC/QA) equipment like thermal profiling with an infrared (IR) scanner and intelligent compaction (IC) rollers.

But all that pales compared to the work they are doing on getting optimum pavement density, so they can improve fatigue life and increase load bearing capacity. Peabody quotes this rule of thumb: Even a 1 percent decrease below minimum density results in a 10 percent loss of pavement life!

The team in Maine has found that the enemy of density is segregation (separation of the coarse aggregate particles in the mix from the rest of the mass). Segregation is a major cause of premature pavement failures. Unfortunately, segregation is a subjective value – It may not even be apparent at the time of construction, making it very difficult to enforce contractually.

Looking for ways to change that, Maine began pilot testing a new ground-penetrating radar (GPR) method, which was developed as part of the Federal Highway Administration’s Strategic Highway Research Program (SHRP2). GPR uses electromagnetic wave reflection to “see” through materials and can be used to measure uniformity and potential defect areas in asphalt pavements.

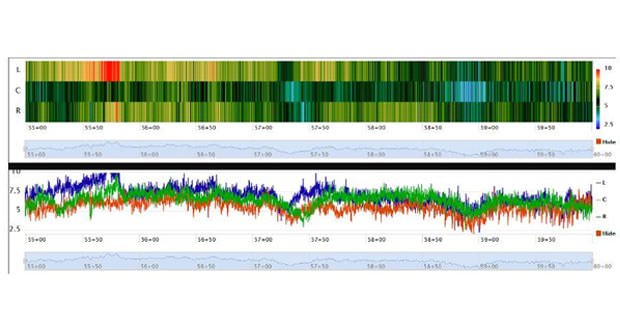

For the pilot testing, Maine is using a new streamlined and operator-friendly GPR device that provides real time profiling of asphalt mixture uniformity and can uncover inconsistencies that mean there are significant variations in density. The device was based on research done by the Texas Transportation Institute (TTI), which worked with GSSI to develop the technology into the PaveScan RDM asphalt density assessment system. The non-contact technology uses a sensor that typically outputs a measurement each half-foot along the lane traveled, so a mile’s worth of data includes roughly 10,000 measurements for each sensor used.

The device arrives at density by measuring the dielectric properties of the asphalt surface. The dielectric constant is the ability of a substance to store electrical energy in an electric field. For example, air dielectric is 1.00059; asphalt aggregate is about 3 to 6; while the dielectric of water is 80. With new pavement, the mixture is uniform; dielectric variation occurs primarily due to the percentage of air voids – which directly correlates to density. The measurement is based on the ratio of reflection from the asphalt surface to the reflection from a metal plate.

Maine, one of several states conducting pilot studies with the equipment, uses 2 gigahertz (GHz) sensors mounted on a portable push cart that can scan up to a 6-foot width. Each antenna collects a continuous line of dielectric/density. An onboard computer captures dielectric values, which can be correlated to core densities. Operators scan a pavement section and the device identifies high, low, and median density locations. They take a static reading directly over each location, obtain cores at each location, and then test the cores, entering the results in the software. Correlation accuracy depends on obtaining core densities over the entire range of measured dielectric values.

To date, Maine DOT has collected data on about a dozen recent paving projects and found that the data aligns well with what they have seen in the field with other measurement options, offering them a better way to ensure they are achieving desired density ranges.

Despite the accuracy, the team still has concerns about the thorny problem of just who will be collecting the data. In the long run the thinking is that it might be best if this type of data could be collected in a moving vehicle that could travel from project to project. The downside of this approach is that there would be a lack of real time data that contractors could use to make adjustments.

Stay tuned to see more reports from the field from those looking for how to effectively manage GPR data to make near-real time changes during production, and get timely reports to project personnel so they can make adjustments on the fly.